Una cortadora de carne es una herramienta esencial tanto en cocinas comerciales como profesionales, diseñada paraCortar carne (y otros alimentos) en rodajas precisas y uniformes de forma rápida y seguraA continuación, se detallan sus principales usos y beneficios:

Usos principales de una cortadora de carne

-

Corte consistente

- Crearebanadas uniformes de carne (por ejemplo, jamón, rosbif, prosciutto) para control de porciones, envasado o emplatado.

- Ideal para restaurantes, tiendas de delicatessen y supermercados que necesitancortes idénticos para sándwiches, tablas de embutidos o envases para venta minorista.

-

Procesamiento de alto volumen

-

Automatiza tareas de corte repetitivas, ahorrando tiempo y costes de mano de obra en plantas de procesamiento de alimentos, carnicerías o empresas de catering.

- Puede cortar300–800 kg de carne por hora (modelos industriales), superando ampliamente el trabajo manual.

-

Preparación de alimentos versátil

- Rebanadaqueso, verduras, pan o carnes congeladas (por ejemplo, tocino, salami) con ajustes de grosor ajustables (0,2 mm–50 mm).

- Algunos modelos cortan en cubitos, en juliana o separan la carne de los huesos.

-

Seguridad mejorada

- Reducelesiones relacionadas con cuchillos con características como protectores de cuchillas, paradas de emergencia y bandejas antideslizantes.

- Las cortadoras industriales cumplen con la normativaNormas de seguridad ETL y CE Para uso en el lugar de trabajo.

-

Calidad mejorada del producto

-

Previene el desperdicio minimizando cortes desiguales o desmenuzamiento de la carne.

- La precisión guiada por láser garantiza una “precisión de ±0,2 mm”, fundamental para productos premium como salmón ahumado o carnes curadas artesanalmente.

¿Quién utiliza cortadoras de carne?

-

Carnicerías:Prepara cortes listos para la venta minorista para los clientes.

-

Restaurantes y delicatessen: Corta carnes y quesos para sándwiches, ensaladas y aperitivos.

-

Plantas de procesamiento de alimentos:Procesa grandes cantidades de carne para envasado y distribución.

-

Servicios de catering:Garantiza una preparación eficiente para grandes eventos.

-

Cocinas caseras (modelos más pequeños): Para aficionados que curan carnes o organizan reuniones.

Ventajas clave sobre el corte manual

-

Velocidad:Corta 10 veces más rápido que a mano.

-

Higiene:Las superficies de acero inoxidable y las piezas extraíbles simplifican la limpieza.

-

Personalización:Ajuste el grosor para obtener carpaccio muy fino o filetes de corte grueso.

-

Durabilidad:Las hojas de grado industrial (por ejemplo, de acero alemán) soportan un uso diario intensivo.

Ejemplos de aplicaciones

- Una tienda de delicatessen utiliza una cortadora para preparar50 kg de pechuga de pavo Sándwiches para la hora punta del almuerzo.

- Una fábrica de alimentos cortabloques de carne congelada en tiras de tocino para envasado al por menor.

- Un steakhouse garantizacortes de chuletón uniformes de 10 mm Para una cocción consistente.

¿Por qué invertir en una cortadora de carne?

Para las empresas, una cortadora de carneAumenta la eficiencia, reduce el desperdicio y mejora la presentación del producto., lo que impacta directamente la satisfacción del cliente y las ganancias. Los modelos industriales también ayudan a cumplir conregulaciones de seguridad alimentaria (por ejemplo, HACCP) a través del diseño higiénico y precisión trazable.

¿Necesita ayuda para elegir el modelo adecuado? [Explore nuestras cortadoras de carne de calidad profesional] o [contacte con nuestro equipo] para una consulta gratuita.

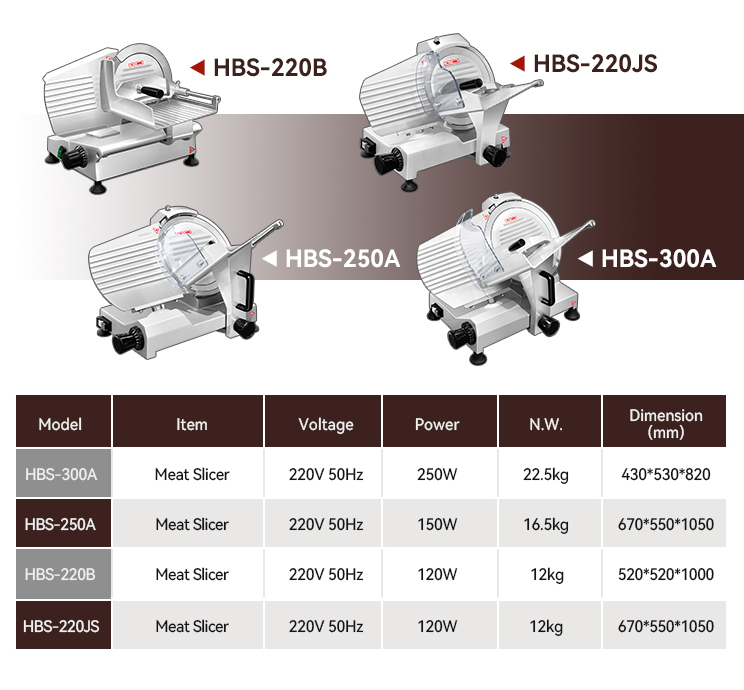

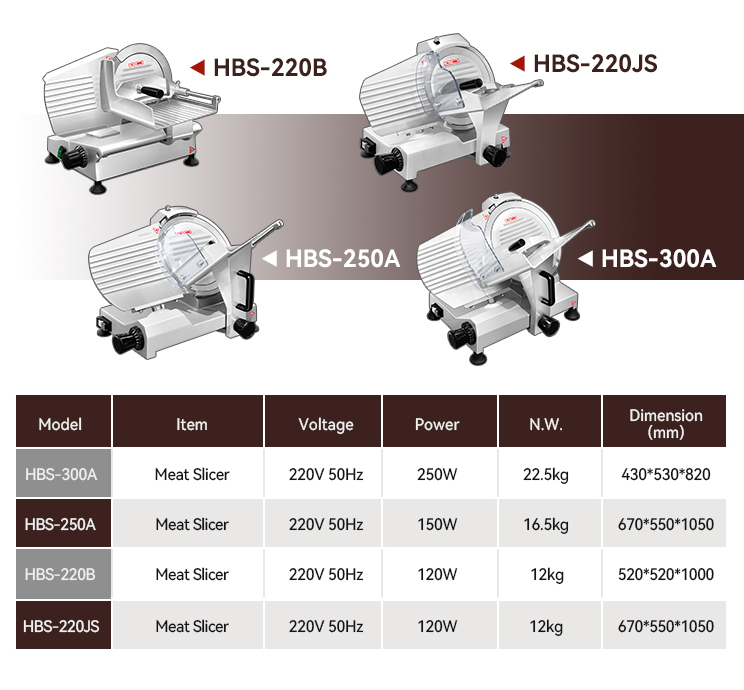

Recomiendo los productos HONGLING para satisfacer sus necesidades.

Por favor contáctenos si está interesado en nuestros nuevos productos.